The pictures of of the recently restorred American Toolworks Shaper

Before

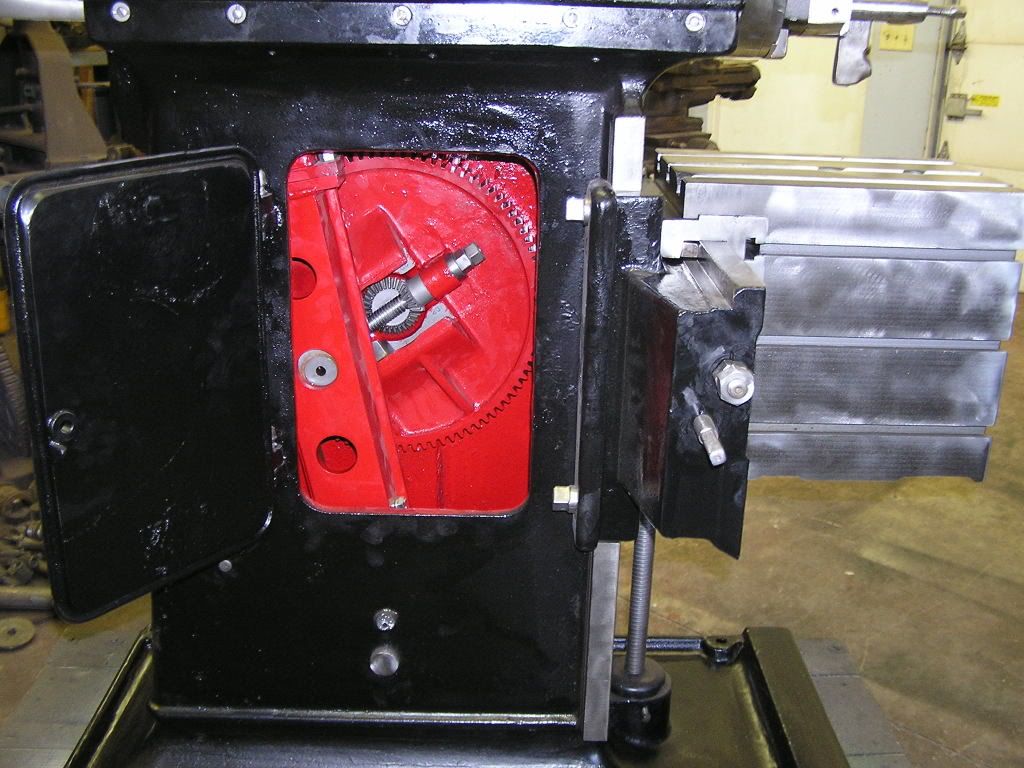

LH side of the machine after a little cleaning up

RH side of the machine after repairs

Most mechanical shapers have what's called a Witworth Quick return mechanism. This allows the machine to have a slow, high force power stroke and a quick return. The leadscrew at the center allows the stroke distance to be varried. This machine also has a 2 speed transmission (nothing but the best for the WMSTR shop)

Before

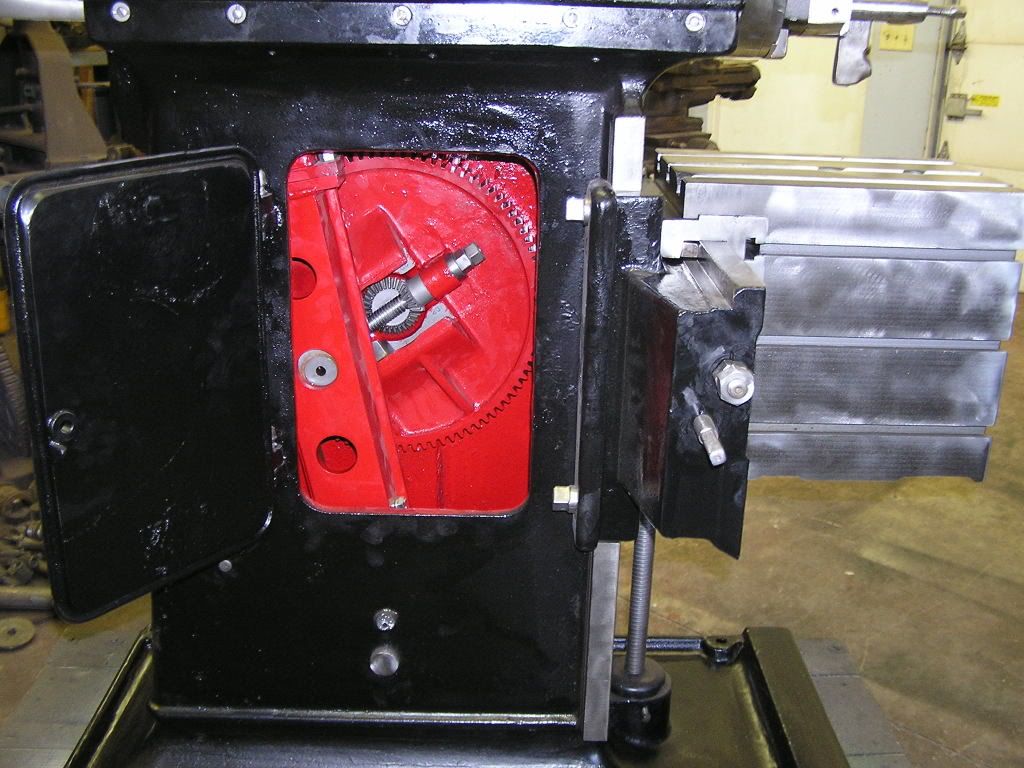

LH side of the machine after a little cleaning up

RH side of the machine after repairs

Most mechanical shapers have what's called a Witworth Quick return mechanism. This allows the machine to have a slow, high force power stroke and a quick return. The leadscrew at the center allows the stroke distance to be varried. This machine also has a 2 speed transmission (nothing but the best for the WMSTR shop)